Coloba Sewerage Treatment Plant, Mumbai -Pilot Project

Authors

Dr. Uday G. Kelkar, P.E., BCEE,

Mr C H Kandalkar, Mr P B Bandgar, Mr S V Patil, Mr S S Deshpande, Mr N G Lalge, Mr R B Datir, Vidyadhar Sontakke, Dr. Yogeshwar Gokhale, Abhay Gadgil, Ajit Savadi, CEng FICE

Dr. Ravikumar Joseph, Nilaksh Kothari, Viraj DeSilva and David Jackshon

Evaluating the sustainability of Direct Potable Reuse from Advance Tertiary Treatment of wastewater to meet United Nations SDG6 Goal

1. Introduction

The city of Mumbai was originally a cluster of seven islands inhabited by local fishermen. Mumbai city witnessed growth during British times when the East India Company took charge of Mumbai and started using Mumbai as the centre of their commercial activities. The land between the seven islands was reclaimed to create Mumbai as a large single island. Initially the water demand of the city was fulfilled by drawing water from wells and tanks which quickly became inadequate. Mumbai being an island was devoid of any perennial river as a source of water. However, there were many rivers that were discharging water from the nearby mountains into the sea. Arresting this water was considered to be the beter solution. Dams were thus constructed on the east and north east side of Mumbai to create large reservoirs to meet the growing needs of the city. Mumbai currently has 6 such schemes supplying water to the population. The water is transmited through large diameter gravity mains covering a distance of more than 150 km. Modern day Mumbai continued to grow and has seen large population growth driven by the commercial activities in Mumbai.

The current population of Mumbai is approx. 14.08 million. BrihanMumbai Municipal Corporation (BMC) is the municipal authority responsible to supply water with the Municipal limits covering both Mumbai City and Suburbs.

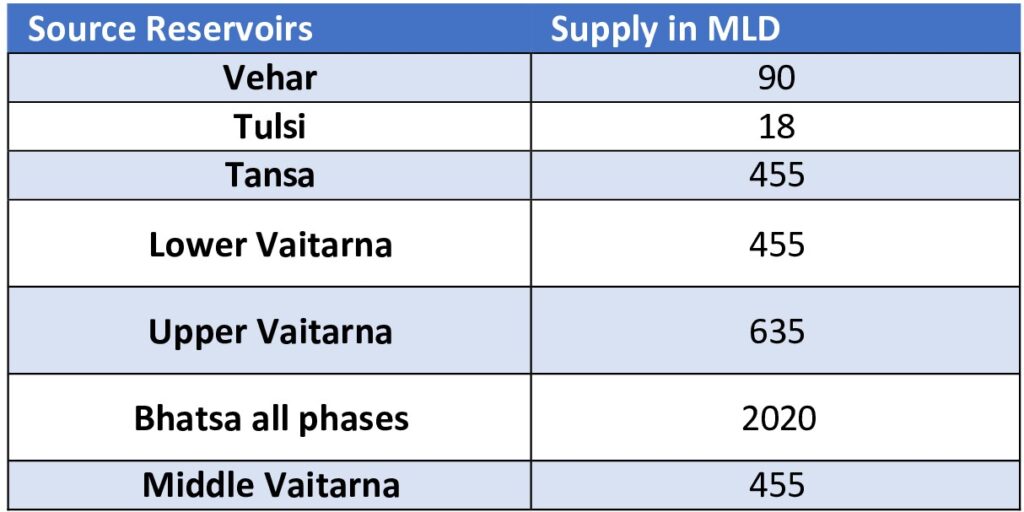

Mumbai existing water supply sources are :

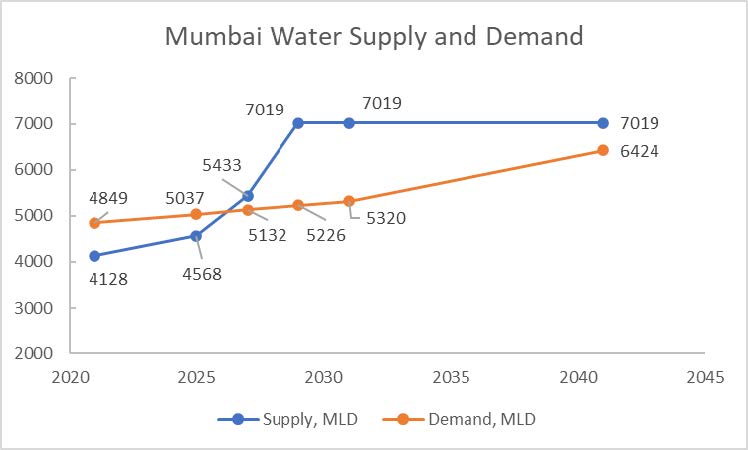

Despite the huge quantity of water being supplied, due to consistently growing demand, major scarcity of water supply is anticipated. The projected water demand for year 2031 and 2041 is approx. 5320 and 6424 MLD (5320,000 and 6424,000 cu m/day) respectively. Construction of large reservoirs is under planning to meet the growing demand.

1.NJS Engineers India Ltd NJS Engineers India Pvt. Ltd.

2. Brihanmumbai Municipal corporation (BMC) – Water Supply Project Department

3. Independent Consultant

4. Freese & Nichols, Texas, USA

Figure 1 : Mumbai Water Supply and Demand

BMC has been planning to meet the ever-growing demand of supply of potable water, by looking into various options, including long term and short solutions. Source Augmentation is certainly one of the available options, however it’s a long term option as it takes years to develop a source and arrange for transmission of the water from a distance. As a result, Initiatives undertaken by BMC include:

- Source Augmentation : Create new sources or augment existing sources to draw more water

- Demand side Management: Metering, Telescopic rates, pre-paid water

- Supply Side Management: Water Distribution Management, NRW reduction

All the above initiatives are long term initiatives. However, as the gap in demand and supply is an immediate concern, BMC is also working on various solutions such as implementing seawater desalination as well as water reuse facilities. Since the water sources are finite and water is too precious for a single use. Used water (domestic wastewater) Treatment and Reuse has become a potential option that can help in minimizing Demand-Supply gap. In recent years, worldwide, this practice of using used water for developing pure water has increased with considerable public acceptance and awareness.

2. Used Water Treatment and Reuse

To meet the growing demand in future, BMC, is also looking at some long-term solutions to meet the Sustainable Development Goal 6 (SDG 6) in envisaging the availability and sustainable management of water for all, by 2030. As such, used water treatment and reuse is being considered very proactively by BMC.

Mumbai generates approx. 2465 MLD (2465,000 cu m/day) of used water (sewage) through its seven sewage treatment plants. The overall potential for reuse has been considered as 1233 MLD (1233,000 cu m/day). However, as the large sewage treatment plants are still under construction and will take couple years to be in operation, BMC is proposing to undertake an Advance Tertiary Treatment Plant (ATTP) pilot project of 12 MLD (12,000 Cu m/day) capacity at its existing & currently operating Colaba Wastewater Treatment Facility (WwTF). The ATTP will receive, tertiary filtered water from the WwTF as inlet water and will be designed to further treat this water to produce potable grade that will have quality similar to the water quality being provided by BMC to its consumers.

3. Water Reuse Scenarios

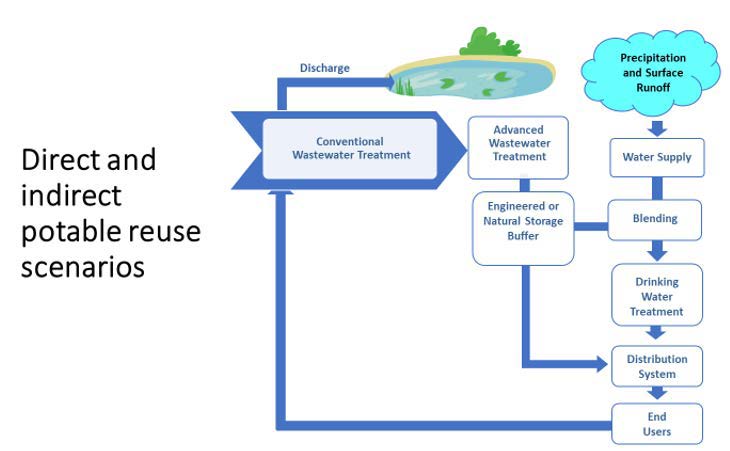

World over, water recycle and reuse is typically observed & categorised in 3 ways; Defacto, Indirect and Direct. At Colaba WwTF , BMC is developing this pilot project in an atemp to produce potable grade water. In the conventional wastewater treatment plant, the treated wastewater is discharged into the waterbodies. In case of Indirect Potable or Direct Potable reuse, the high quality treated used water (wastewater) is further treated by advanced processes and is passed through a natural or engineered buffer in order to ensure additional safeguards prior to its distribution/consumption.

Figure 2 : Direct and Indirect Reuse Scenarios

4. Colaba Advanced Tertiary Treatment Plant (ATTP)

The existing Colaba WwTF in South Mumbai, commissioned by BMC in 2020, is a 37 MLD (37,000 cu m/day) capacity municipal sewage treatment plant consisting of sequential batch reactor (SBR) process that is followed by Disk Filtration as a tertiary treatment. The Proposed Colaba ATTP will take the tertiary treated water from the outlet of the disk filter to further treat in order to make potable water for potential supply it to the nearby “A ward” area of Mumbai.

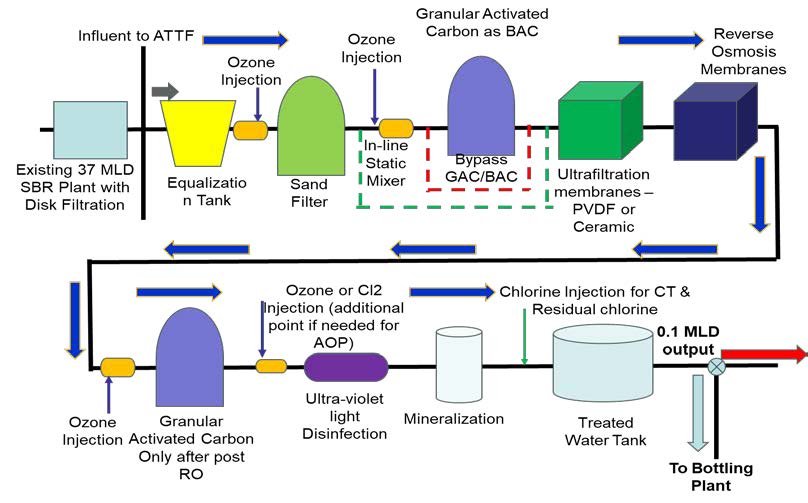

The primary objective of this unique and first-of-its-kind project in India is to establish a 12 MLD full scale advanced tertiary treatment plant (ATTP) as well as a 0.1 MLD (100 cu m/day) pilot ATTP facility mounted inside a Trailor and operate for number of years while simultaneously conducting public awareness and capacity building activities. It is envisaged that in the future, the 0.1 MLD pilot facility can be moved to various other wastewater treatment plant locations in Mumbai to experiment and ensure the same or slightly modified treatment process can be adopted for developing potable water at these locations.

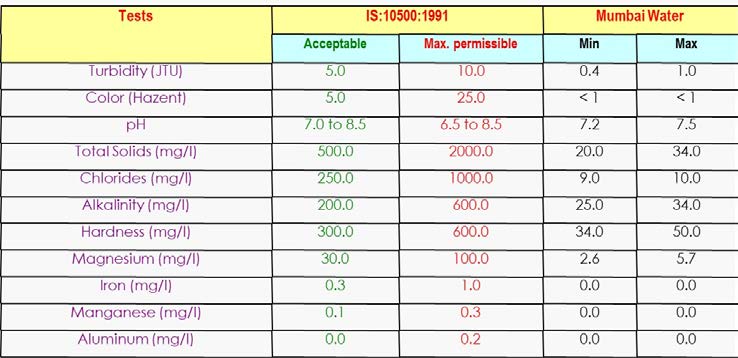

The aim at the Colaba ATTP is to generate water that will be of equal or higher quality with the quality of water that BMC currently supplies. The table 2 below provides details of Mumbai’s present water quality results

Table 2 : Mumbai’s Water Quality

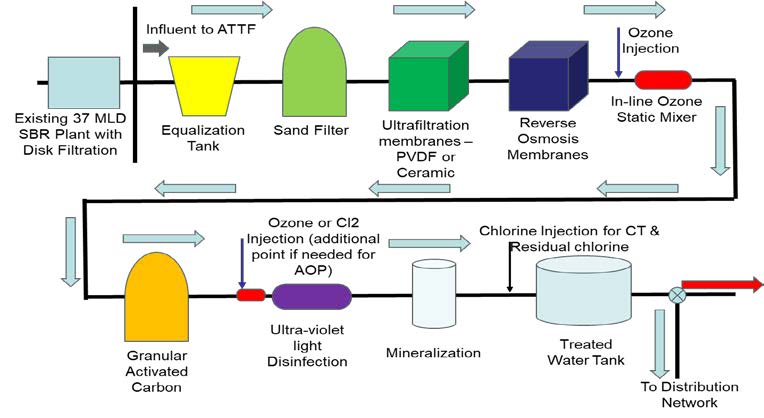

The Direct Potable Reuse (DPR) project will have a treatment process based on worldwide practices and will consist of Ozone, GAC/BAC, Ultra Filtration, Reverse Osmosis, Ultraviolet disinfection with or without Advance Oxidation Process (AOP), remineralisation facility with chlorine for distribution residual management. The entire process in the proposed ATTP is being considered to get a multiple barrier approach in mitigating risks associated with physical, chemical and biological contaminants while producing water of drinkable quality. Apart from technical and engineering designs and construction, this project also envisages extensive public awareness and capacity building campaigns to remove the stigma of reusing of used water (wastewater) for Potable applications.

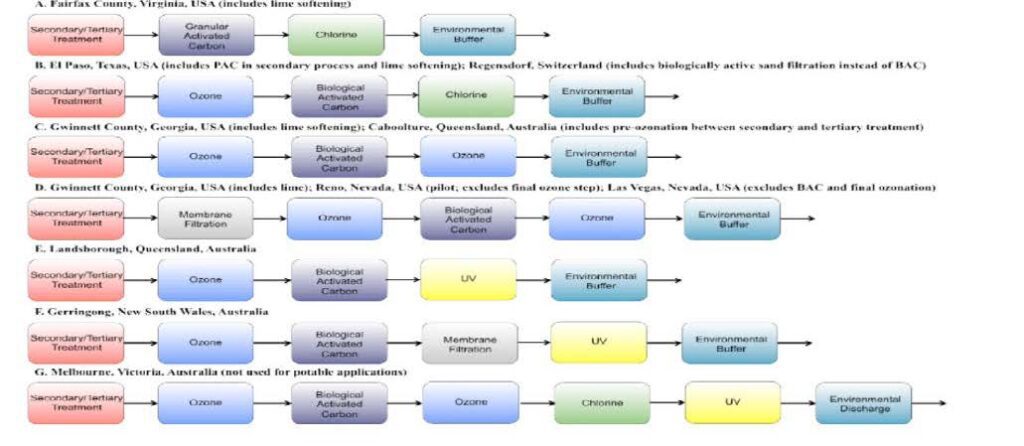

Figure 3 : Combination of treatment processes used in DPR projects; worldwide

At the Colaba DPR plant, it is proposed that the water will be supplied directly to the community, utmost precaution is needed in the view of public safety and hence it is absolutely necessary to construct an engineered environmental buffer, with a residence time of minimum of 24-hrs before the water is sent to the distribution system. For the DPR project, it is envisaged that the process stream so designed, will achieve more than 12 to 14 Log removal of Microbial contaminants.

5. Proposed Treatment

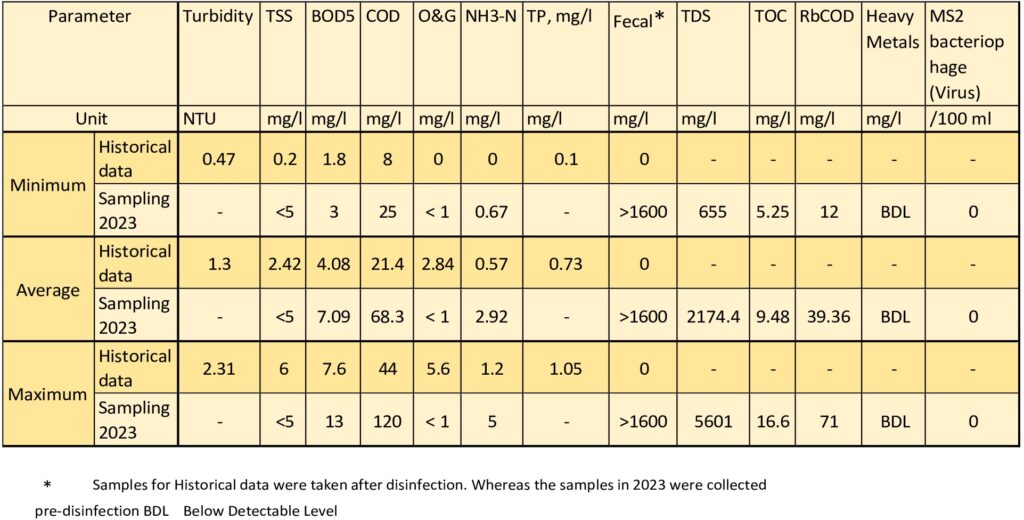

At present extensive sampling exercise is being carried out to assess the quality of wastewater that will be taken further for the advance treatment process. The results of the initial analysis and the historical data is presented in the table below :

Table 3 : Wastewater Analysis

Based on the analysis and global trends in the ATTP processes a tentative treatment process train customised for the local conditions and allied constraints have been considered. The space availability is a major constraint at the plant site and the processes have been planned considering the available space. While designing the plant layout, a special consideration has been given to protect a very old large banyan tree in the middle of the space allocated for the plant. The ATTP layout will be developed in such a way to potentially protect the tree and avoid chances of relocation. The tentative process flow for the main 12 MLD (12,000 cu m/day) plant and the 0.1 MLD (100 cu m/day) pilot plant is provided below. The process for 0.1 MLD pilot plant is being developed to have a flexibility in unit operations to assess the performance by altering sequences of the processes to determine the most optimum treatment process train. The data generated during the operation of the 0.1 MLD prototype will be immensely useful not only for fine tuning the process but also for developing confidence in the public and to evolve an effective Public Outreach Programme.

Figure 4: Tentative Process Flow Diagram – 12 MLD Advance Tertiary Treatment Facility (ATTF) & 0.1 MLD Pilot ATTF

Figure 5: Process Flow Diagram with alternative arrangement of units –0.1 MLD pilot ATTF

6. Public Outreach

Public Outreach is absolutely essential for success of the ATTP concept. Trust is the most importance factor. Public awareness and acceptability will play a major role towards achieving the goals of augmenting BMC’s water resources. As part of this project the project team has planned an extensive Information Education and Communication (IEC) programme to be deiminated over the next several years . The IEC programme will be based on the proven guidelines, that include but not limited to:

- Make the outreach program strategic, transparent, and thorough

- Build on lessons learned from existing worldwide potable reuse projects, research on relevant issues like CECs, and available communication strategies (such as risk communications)

- Start outreach early and engage the public throughout the lifetime of the project

- Use proven techniques and tools to listen to and communicate with the community, engage the media, and address public concerns

- Provide useful information to explain the role of water reuse in the water cycle, increase awareness of the value of potable reuse, and build confidence in the quality of ATWT – Trust is most important in Data Generated and

- Create messages that are consistent and communicated to the entire community, including different audiences

- Build relationships with influential community members (e.g., opinion leaders)

- Create transparency in all aspects of the project, including costs, water quality, and safety

- Prepare for tough questions and address misinformation

7. Summary

For evaluating the efficacy of treatment trains within an ATTP, focus is given on certain key factors, including the following:

- Treatment trains to be capable of producing water that meets published guidelines or health advisory levels

- Constituents/parameters used for establishing performance occurring within the source water at a high frequency and at sufficient concentrations to allow for a large dynamic range for evaluating treatment trains

- Availability of appropriately sensitive and specific analytical methods

- A diversity of constituents that are broadly representative of the various types of constituents of health concern that could be present in wastewater

- An array of constituents with different properties that affect their removal by various unit processes within a treatment train

- Real-time online monitoring is very essential for maintaining standards and get the real